Portable Dust Free Blast Machine is a light-weight,portable abrasive blasting tools with an integral abrasive recovery system.During Blasting,abrasive is continually recycled,while dust and other debris are collected in a slip-on dust bag Interchange adapter boots for level surfaces,corners,etc.fit over the swive blast head to assure efficient recovery on any surface.

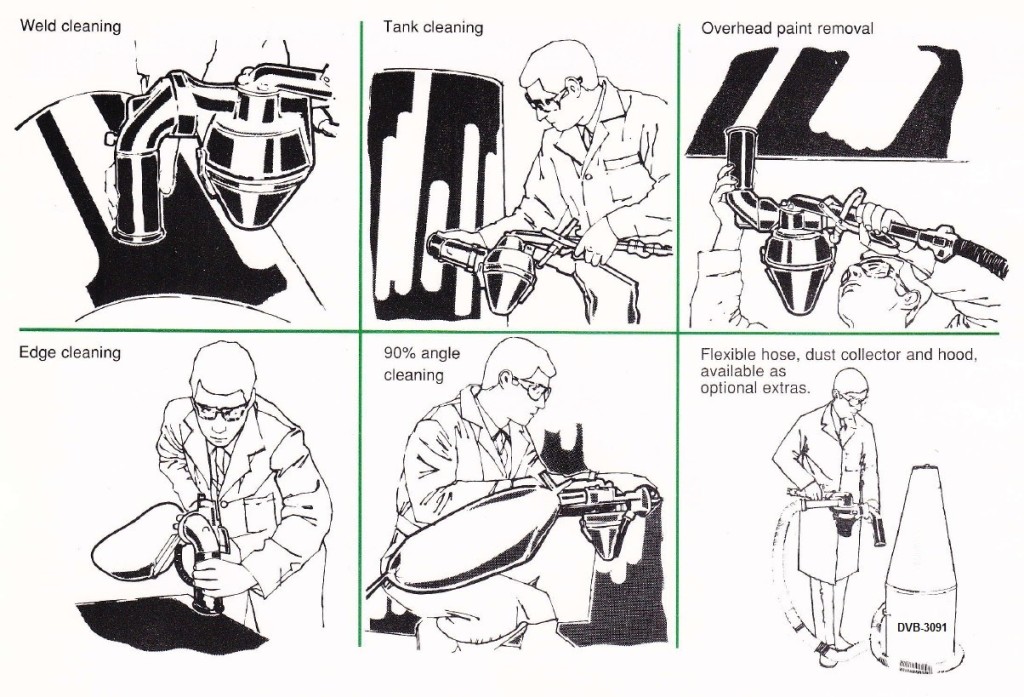

Application Photo

Feature

- Lightweight

Machine weight only 7 lbs (3 kg) plus up to 4 lbs (2 kg) abrasive charge.

- Compact

Small enough for being used in the “hard-to-get-at areas”.

- Flexible

Swivel head – use at any angle.

- Time saving

Always ready for action – simply couple 3/4″ (19 mm) air line and start

blast cleaning.

- Recycles abrasive

Re-usable abrasives, i.e. steel shot and grit, chilled iron, aluminum

oxide, silicon carbides, glass beads, etc. can be used.(40 ~100Mesh is advised).

- Double action lever

No dismantling to recharge empty abrasive container. First pressure

picks up new abrasive charge or vacuums the work surface. Second

pressure starts blast cleaning/recycling operation.

- Air pressure only – no other form of power supply needed

Requires 33-60 CFM at 9-100 lbs P.S.l.

Blast pattern approximately 1 1/4 (32 mm) wide.

- Alternative dust collection method

Flexible hose with dust collector and hood available

| Model | Volume (Abrasive/kg) |

Air Consumption (m3/min) |

Spray Swath(mm) | Capacity(m2/h) | Weight

(Kg) |

| DVB-3091 | 2 | 1.5 | 50 | 2-5 | 3 |

.

Portable Dust Free Blaster is well suited for spot cleaning,removing weld spatter, and deburring cut metal edges. Special attachments let you blast inside and outside corners, and on rough surfaces. This will be a reliable base for anti-corrosion paint, metallising or plastic coating. The swiveling nozzle makes it easy to operate, allowing blasting in every direction. It is a handy tool that can be used under cramped conditions. The nozzle is encased in a rubber cowl, which is applied at right angles to the workpiece. Specially designed cowls are available for angled surfaces, pipes, sheet steel edges, etc. The unit can be adapted for use by left-handed operator. Lightweight and handy, It weights only 3 kg.

It recycles abrasives and grindings so effectively that other types of work can be carried out in the immediate vicinity, and there is no need to cover up sensitive equipment, such as machine components.

Advantage:

* Constant cleaning of internal surface

* Cleaning with the highest speed possible

* Saving on time and abrasives

* Adjustable setup for the best cleaning speed

* Easy handling and no down-time

* Blast in only one drive through

* Adjustable for all kind of abrasive

* Very rigged construction

* Suitable for all kind of pipe internal diameters

* Semi-automatic,one operator can handle more machines or do other work

WhatsApp us

WhatsApp us