Application:

Aluminium profiles,security doors

Solar water heaters,insulation tank

Ship Carbin,

Refrigerators,Packing Model

Road construction,Wall insulation,

Gap Filling,Pipe insulation

General Introduce:

Polyurethane Foam Pouring Machine is made by mixing and reacting chemicals to create a foam. The mixing and reacting materials react very quickly, expanding on contact to create foam that insulates, air seals and provides a moisture barrier. SPF insulation is known to resist heat transfer extremely well, and it offers a highly effective solution in reducing unwanted air infiltration through cracks, seams, and joints.

Polyurethane Foam Pouring Machine Benefit:

Prevents Air,mositure,vapor and sound infiltration

Reduces energy usage and heating and cooling costs

Increases building and occupant comfort

Meets new building codes and green building certificate

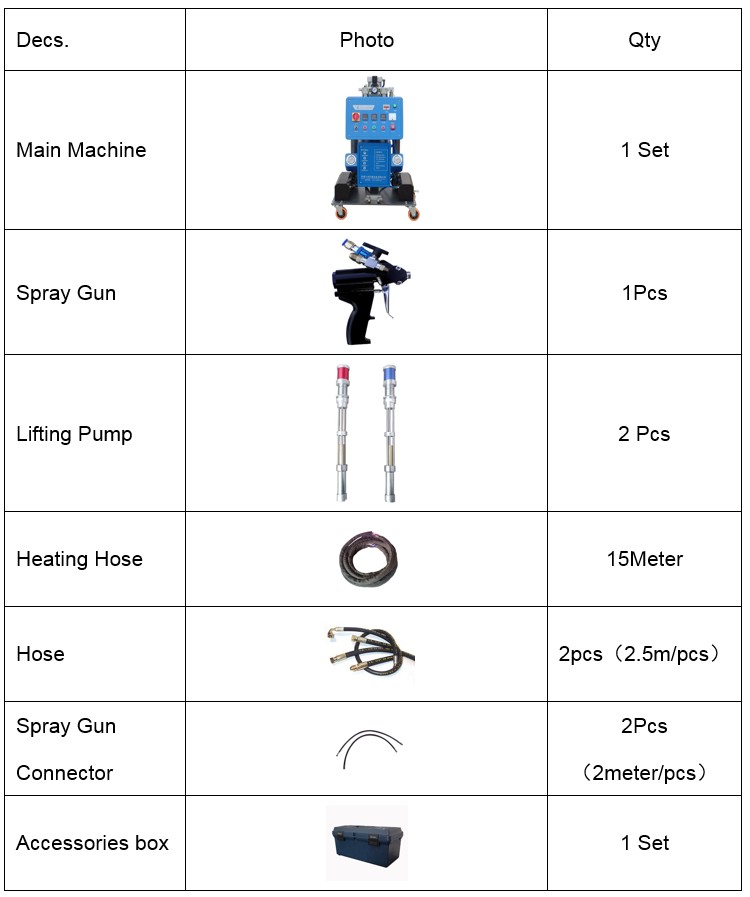

Standard Configurations:

Model: PUI-Q2600D, Q2600D15 Polyurethane Foam Injecting Machine

Power:Single Phase 220V 50HZ;3 Phase 4 Wires 380V 50HZ

Heating power:11KW

Driven: Pneumatic

Air source:0.5~0.8 MPa

Air capacity:≥1.2m3/Min

Q2600D Flow Capacity:2~8kg/Min; Q2600D15 Flow Capacity: 2~15kg/Min

Max output pressure:11Mpa

AB material output ratio:1:1

Heating Hose: 7 Meter

Max output distance:60 meter

Package: Wooden

Packing Dimension:910mm X 890mm X 1300mm

Gross Weight:116KG

1. Pneumatic driven, with small volume, light weight, low failure rate, simple operation,easy operation

2. Feeding volume can be adjusted,Timing and Quantitative,

3. Advanced reversing direction method, make sure working stability.

4. Minimizing spraying block with multi-filter device

5. Multi-leakage protection system to protect the safety of the operator.

6. Equipped with emergency switch system, help operator deal with emergence rapidly

7. Heating system enables rapid warming of raw materials to the best working situation, speeds up normal operation progress.;

8. Digital counting system can understand original consumption timely.

WhatsApp us

WhatsApp us